Using the Past to Create a Better Future

In late 2016, Matthew J. Brax embarked on a journey across the United States of America, eventually finding his way to the colorful state of Colorado. Along the way, he encountered numerous challenges with tires, sparking his determination to find a better solution. One fateful day, while looking at car magazines in a store, he noticed the shelf’s remarkable combination of strength and flexibility. Recalling the tale of Jenney, an engineer he had heard about during his kayaking adventures on the Chicago River, Matthew’s inspiration began to crystallize. Legend had it that Jenney had fixed the issue of collapsing buildings after the tragic Great Chicago Fire. His revelation came when he witnessed his wife placing a hefty book atop a wire birdcage, prompting the notion that an iron framework could provide structural support for buildings. For years thereafter, Matthew delved into research and prototyping, persisting with his endeavors even amidst the challenges of the pandemic.

The Home Insurance Building weighed only a third as much as it would have in stone. Photograph: Corbis

For obvious reasons, when the New York Home Insurance Company sought a new Chicago headquarters in the bustling downtown area, they prioritized fireproofing while also aiming for grandiosity in size. Jenney’s innovative metal-framed design emerged victorious in their open contest, heralded for its fire-resistant materials and enhanced protective features.

Fighting Global Warming & the Dangers of Heat

The photograph above shows a blowout caused by heat stress

ReCo Technology (Reactively Combined Technology) is a versatile framework capable of implementing a range of capabilities.

ReCo Tech (Reactive Combined Technology) is the framework for MolAct Tires, a revolutionary advancement in tire technology. It represents a new paradigm in material science and engineering, pushing the boundaries of what’s possible in tire design and performance. This cutting-edge framework lays the foundation for a variety of next-generation developments in the automotive and tire industries.

MolAct Tires leverage ReCo Technology to support vehicle weight while actively managing heat, punctures, and extreme conditions. Integrated air pockets within the tires monitor pressure, ensuring alignment with Tire Pressure Monitoring Systems (TPMS) for optimal safety & performance, as well as compliance & regulation.

Tire failures are a serious safety concern, accounting for nearly 11,000 vehicle accidents each year and resulting in over 500 fatalities, according to the National Highway Traffic Safety Administration (NHTSA). In the U.S. alone, approximately 220 million flat tires occur annually—roughly seven punctures every second—leading to frequent roadside emergencies for drivers.

It’s projected that this technology could avert approximately 10 million flat tire-related issues for first responders in the U.S. over the next three decades

A significant contributor to tire failures is under-inflation, responsible for 90% of incidents. When tires are under-inflated, friction increases, causing heat buildup, particularly in hot weather when road temperatures can soar to 150°F. Conventional tires struggle to withstand these conditions, making blowouts more likely and increasing the risk of accidents.

Tire pressure drops in cold weather (causing underinflation) and increases in hot weather (leading to overinflation). Tire pressure changes by approximately 1-2 PSI for every 10°F temperature fluctuation and is recommended to have 32 to 36 PSI for optimal performance, making a tough mark to hit during constantly fluctuating temperature changes.

MolAct Tires, engineered with advanced ReCo Technology, are specifically designed to mitigate these risks. Their innovative structure minimizes friction and heat buildup, virtually eliminating the threat of punctures or blowouts—even in extreme conditions. This makes MolAct Tires a game-changer for road safety, offering a reliable, heat-resistant solution to prevent the hazards associated with tire failure.

As outdoor temperatures rise, so too does the risk of tire blowouts, which can result in the loss of vehicle control and create dangerous debris (commonly known as “road gators”). These hazards present significant threats to drivers and other road users, with mere seconds for drivers to react. The consequences of tire failure can be severe, leading to costly accidents or even fatalities.

MolAct Tires aim to address managing heat, punctures, and extreme conditions. enhancing road safety and reducing the risks of tire-related accidents.

With MolAct Tires, safety is an immediate priority—not just for road use, but also for protecting our planet and supporting the exploration of other planets.

Following Matthew’s car accident, his determination to find a better solution grew.

Towards a Safer & More Sustainable Future

Crafted to uphold structural integrity independently of air pressure, MolAct Tires (Molecularly Active Tires) are engineered for durability even in harsh conditions. With a focus on sustainability and safety, they provide valuable insights while catering to eco-conscious individuals and those in search of energy-efficient travel options. Opting for MolAct Tires signifies a dedication to both environmental preservation and cutting-edge transportation solutions.

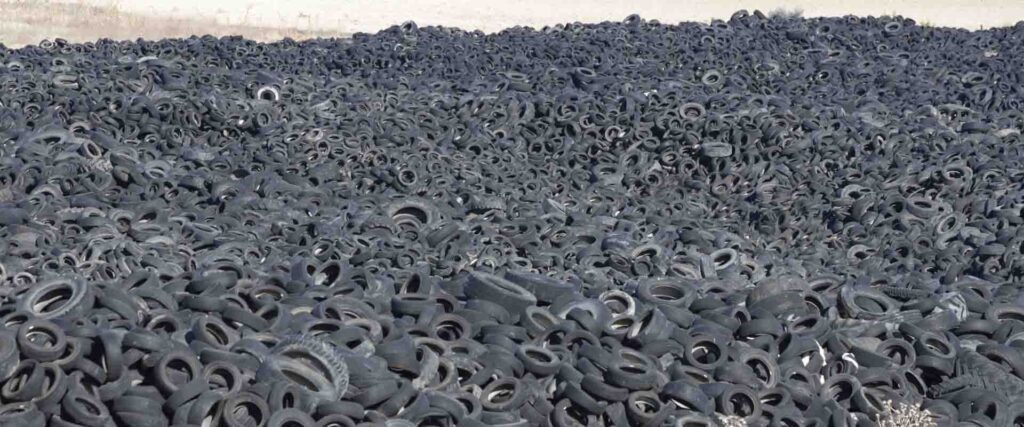

Did you know?

– 600K tires went into the ground in 2020

– Tire mountain hold 26 million tires

– Mosquito- borne epidemic can launch a disease from our own backyard that we ordinarily have to travel to the tropics to acquire.

– You have to pay to store hazardous end-of-life tires.

– Some researchers estimate that 10-28% of all micro-compound waste in the sea is from used tires.

– Tire fires can burn up to 9 months, releasing toxic carcinogenic and mutagenic toxins into the air.

– Tire waste is often found in natural environments such as creeks, rivers, and oceans.

– 1 to 2 billion tires are disposed of each year.

– 2-3% of all waste materials are collected.

By choosing tires with low rolling resistance, both consumers and fleet operators can improve fuel efficiency, reduce CO2 emissions, and lower operating costs over the life of the vehicle.

Tires can contribute to environmental problems and impact the Earth in several ways:

Resource Extraction and Manufacturing: The production of tires involves extracting and processing raw materials, such as rubber from rubber trees, oil for synthetic rubber, and various chemicals. The extraction and manufacturing processes can result in habitat destruction, deforestation, and pollution.

Natural rubber, which requires large-scale monoculture plantations. These plantations can contribute to deforestation, loss of biodiversity, and soil degradation.

Synthetic rubber is derived from petrochemicals, meaning that its production contributes to fossil fuel consumption and greenhouse gas emissions.

Air Pollution during Production: Carcinogenic & mutagenic toxins also release into the atmosphere when burned. Only expensive 02 emission equipment can safely burn the tires to a recycled state safely (which isn’t profitable). These emissions can contribute to air pollution and have adverse effects on human health and the environment.

Recycling: Because of the problems with effectively recycling these hazardous tires, the US alone adds roughly 300 million end of life tires annually.

Waste Generation: Tires pose a significant waste management challenge. When tires reach the end of their life, they can become a source of environmental pollution if not disposed of properly. Improperly discarded tires can accumulate in landfills or illegal dumpsites, leading to habitat disruption and potential leaching of harmful substances into the soil and water. Mosquitos can use these tires as breeding grounds that can carry diseases like Malaria and the Zika virus. Some estimate that 10-28% of all micro-compound waste in the sea is created by used tires.

Fire Hazards: Large tire piles can be susceptible to fires, which are difficult to control and extinguish. Tire waste fires can burn up to 9 months! Tire fires release toxic smoke and pollutants into the air, posing a threat to air quality and human health, including cancer concerns. 1.3 million tires burnt for a couple of weeks as 150,000 gallons of oil burnt, filling the air. With temperatures rising year over year, some believe that tires are the #1 threat to humanity.

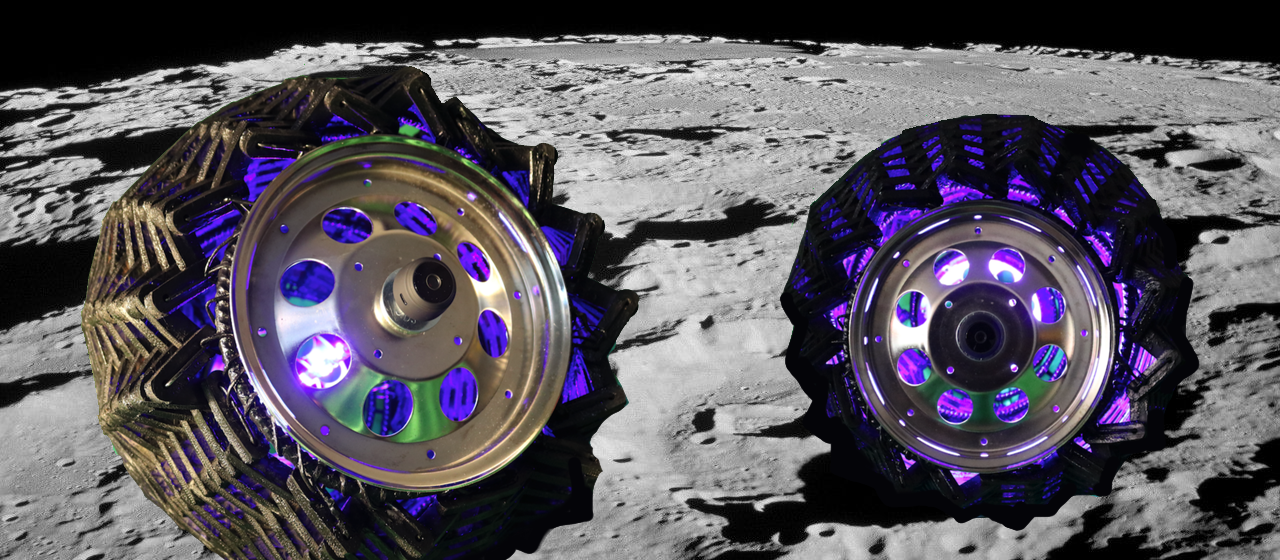

Prototype Testing

MolAct (Molecularly Active) Tires & ReCo (Reactively Combined) Technology utilize state-of-the-art materials. MolAct Tires has successfully patented a functioning system to address issues due to punctures.

From our proven polymer selection to our patented systems (including ReCo Technology), we offer customized levels of application.

Following numerous iterations, we’ve curated a range of functional materials and a viable system for further enhancement, including proven polymers used for automotive airless tires.

To propel our prototypes forward and subject the technology to high-speed and extreme condition testing, we’re seeking funding. Our allocation plan prioritizes investing in an injection mold and purchasing a professionally crafted reactively combined technology framework.

Existing Technology Applications

Although MolAct Tires & ReCo Technology can employ sophisticated materials, they also rely on many common tools for testing, monitoring, and maintenance purposes. Both MolAct Tires & ReCo Technology utilize systems that have undergone testing across multiple prototypes. With the capability to reduce roll resistance and stop deflation from happening, MolAct Tires holds the answer for pushing the boundaries of tire evolution.

Did you know that for the past two decades, vehicles have been required by law to incorporate a Tire Pressure Management System? This mandate has positioned MolAct Tires & ReCo Technology as the sole providers of compatible airless capable technology.

Aviation Case Study

The fatal Learjet 60 accident at Columbia Metropolitan Airport (KCAE) on September 19, 2008, serves as a troubling reminder of the significant risks posed by tire-related malfunctions during critical takeoff phases. The accident underscores a broader issue within aviation: the vulnerability of modern aircraft to tire failures and the challenges these present during high-speed, high-stakes operations. With the go/no-go decision leaving little room for error, tire problems can quickly escalate from a minor issue to a catastrophic one.

In this tragic case, a tire failure occurred just moments after the first officer (FO) called “V1” during takeoff. The cockpit voice recorder (CVR) captured a loud rumbling sound—about 1.5 seconds after the V1 call—marking the catastrophic failure of the first main landing gear tire. Less than half a second later, the FO called “Go,” while the captain, unable to fully assess the situation, responded with something unintelligible. At this point, the aircraft had reached 144 knots. The FO, confused, asked, “No? ar…alright. Get ah, what the [expletive] was that?” The captain, still unsure, replied, “I don’t know. We’re not goin’ though.” Within seconds, the captain initiated full thrust reverser deployment.

Surviving passengers reported that the aircraft swayed uncontrollably, giving the impression that it was “out of control” as it raced down the runway. The Learjet eventually veered off course, passed through the 1,000-foot runway safety area, collided with airport lighting and navigation antennas, and plunged down a steep slope, continuing across a five-lane road before erupting in a fireball. Tragically, the captain, first officer, and two passengers were killed, with two others sustaining serious injuries.

The subsequent investigation by the National Transportation Safety Board (NTSB) revealed critical findings about the aircraft’s tires. All four main landing gear tires showed signs of severe underinflation, a factor that played a key role in the multiple tire failures during takeoff. The tires had lost approximately 2% of their pressure per day in the three weeks leading up to the accident. By the time of the incident, tire pressure had dropped to 140 psi, well below the recommended 219 psi. This underinflation created a dangerous condition, significantly increasing the likelihood of tire failure at high speeds.

photo (c) NTSB; Columbia Metropolitan Airport, SC (CAE); September 2008; (publicdomain)

This accident highlights a critical issue in aviation: the ongoing challenge of maintaining optimal tire pressure, which directly impacts aircraft safety. Despite advances in other areas of aviation technology, the tires remain a vulnerable component, subject to degradation that often goes unnoticed until it’s too late. In this case, inadequate tire maintenance—combined with the stress of high-speed operations—contributed to the failure, with disastrous consequences.

The NTSB concluded that the probable cause of the accident was the operator’s inadequate maintenance of the aircraft’s tires, leading to multiple tire failures due to severe underinflation. Furthermore, the captain’s decision to reject the takeoff after reaching V1, contrary to training and standard operating procedures, compounded the already hazardous situation. The incident serves as a stark reminder that current tire maintenance practices and tire technologies must be reevaluated to prevent such failures, particularly in the critical moments during takeoff when every decision counts.

Bulletproof Tires

Overall, the adoption of airless capable tires for military applications enhances the operational effectiveness, survivability, and sustainability of military vehicles, contributing to mission success across a diverse range of operational environments.

Did you know?

Lego produces the most tires by quantity.

Molact Tires snap into place.

MolAct Tires with ReCo Technology offer a range of tactical advantages:

1. Resilience

MolAct Tires are engineered to be nearly impervious to punctures, blowouts, and other forms of damage, greatly reducing the risk of vehicle immobilization in harsh environments. Whether navigating sharp rocks, debris, shrapnel, a nuclear environment, or under enemy fire (ballistic or missile), MolAct Tires provide enhanced durability that traditional pneumatic tires can’t match. This resilience is especially critical in combat zones, where conventional tires are vulnerable to hostile conditions and enemy action.

2. Mobility

Maintaining operational vehicles is a key priority, not just for cost savings but for the safety of troops. MolAct Tires ensure that military vehicles can keep moving, regardless of terrain challenges or weather conditions. By eliminating the need for air pressure, these tires offer reliable performance in extreme environments—whether in freezing cold or sweltering heat—without the risk of blowouts or flats. This ensures that military units can remain agile and responsive on any battlefield.

3. Intelligence and Situational Awareness

MolAct Tires are integrated with Tire Pressure Monitoring System (TPMS) technology, which provides real-time data on tire conditions. This information can be critical for tactical awareness—such as identifying potential threats. For example, the system can detect drops in air pressure caused by enemy fire or other hazards, potentially revealing the direction of incoming attacks. The durable construction of ReCo Tech (Reactively Combined Technology) also supports advanced technological applications, such as data analytics and responsive materials, enhancing overall operational efficiency.

4. Reduced Maintenance

Thanks to ReCo Technology, MolAct Tires require no inflation, reducing the likelihood of punctures or pressure-related issues. This low-maintenance design minimizes the logistical burden on military units, freeing up resources for other critical tasks. Moreover, since temperature extremes have little effect on MolAct Tires, there’s no need to worry about tire performance in freezing cold or intense heat, reducing the need for tire maintenance in such conditions.

5. Extended Lifespan

MolAct Tires are built for durability, significantly extending their operational lifespan compared to traditional pneumatic tires. This longevity is invaluable in military settings, where vehicles endure heavy use and long deployments without access to regular maintenance facilities. MolAct Tires can be retreaded and refilled as needed, making them a cost-effective and long-term solution for military fleets.

6. Adaptability

ReCo Technology is highly versatile and can be adapted to suit a wide range of military vehicles, including armored personnel carriers, infantry fighting vehicles, logistics trucks, and light tactical vehicles. This adaptability ensures that various types of military assets can benefit from MolAct Tires’ enhanced performance and durability. Additionally, the materials used in ReCo Technology can be tailored to respond to environmental conditions, such as temperature shifts, natural disasters, or even extreme scenarios like nuclear warfare, making it an ideal solution for rapidly changing combat conditions.

7. Logistical Efficiency

MolAct Tires improve logistical efficiency by reducing the need for frequent tire replacements and maintenance. Their durability ensures more reliable deployment and sustainment of military forces in the field. Additionally, MolAct Tires use pneumatic rims, which offer weight reduction, making them easier and more cost-effective to ship. In high-stress environments where communication is often lost, maintaining mobility becomes crucial. Whether delivering medical supplies, weapons, or vital personnel, MolAct Tires ensure that military units remain operational in even the most challenging conditions.

Conclusion:

MolAct Tires with ReCo Technology provide critical advantages for military operations, enhancing resilience, mobility, and operational efficiency. With features like low maintenance, extended lifespan, and adaptability to various vehicle types and environmental conditions, these tires offer an optimal solution for military fleets operating in diverse and high-risk environments. Whether in combat zones or during humanitarian missions, MolAct Tires ensure that military assets stay functional and secure, no matter the terrain or threat.

How it works

Choose your design

MolAct Tires use ReCo (Reactively Combined) Technology for resilience.

Trusted Suppliers

DSM’s PL420-H and EM460-88 polymers, combined with Grainger’s strong framework selection, represent a powerful combination for advanced engineering applications. DSM’s PL420-H, a high-performance polyamide, offers exceptional strength, durability, and thermal resistance, making it ideal for applications in automotive, electronics, and industrial equipment. Its robust properties allow for the design of components that can withstand extreme conditions without sacrificing performance. The EM460-88 polymer, also from DSM, provides enhanced impact resistance and superior wear properties, which are especially beneficial in applications requiring long-term reliability under mechanical stress. When paired with Grainger’s framework selection, known for its durable and versatile structural components, the result is a complete, high-performance solution that optimizes both material strength and design flexibility. Together, these materials and components enable the development of cutting-edge products that meet the demands of modern industries.

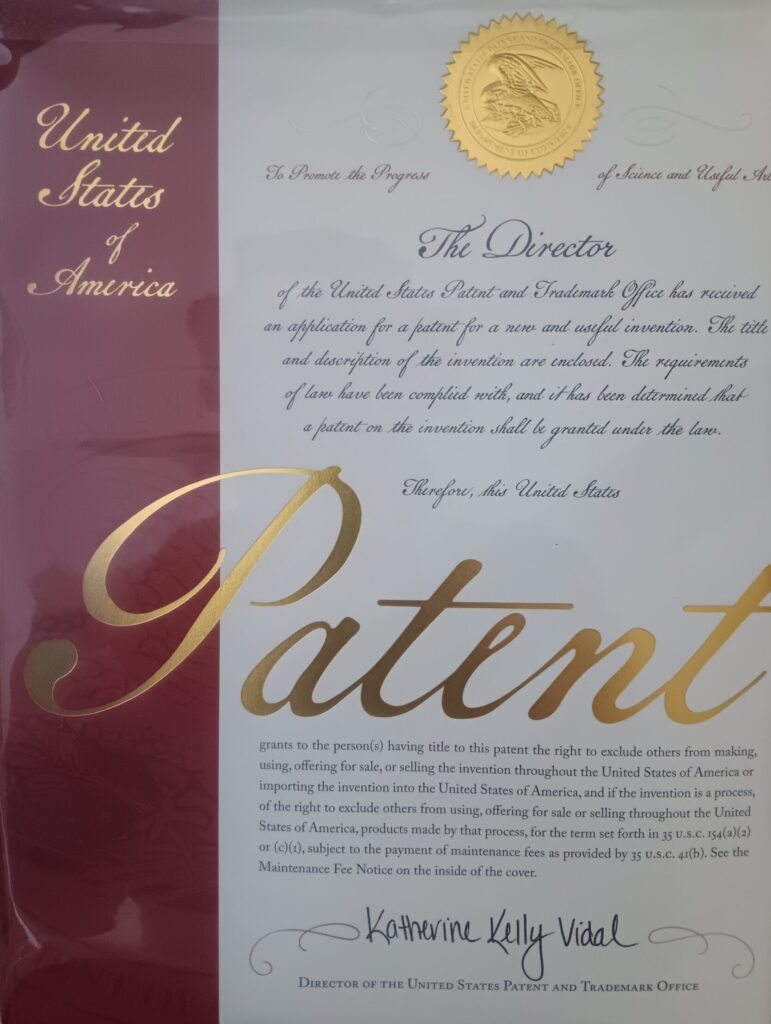

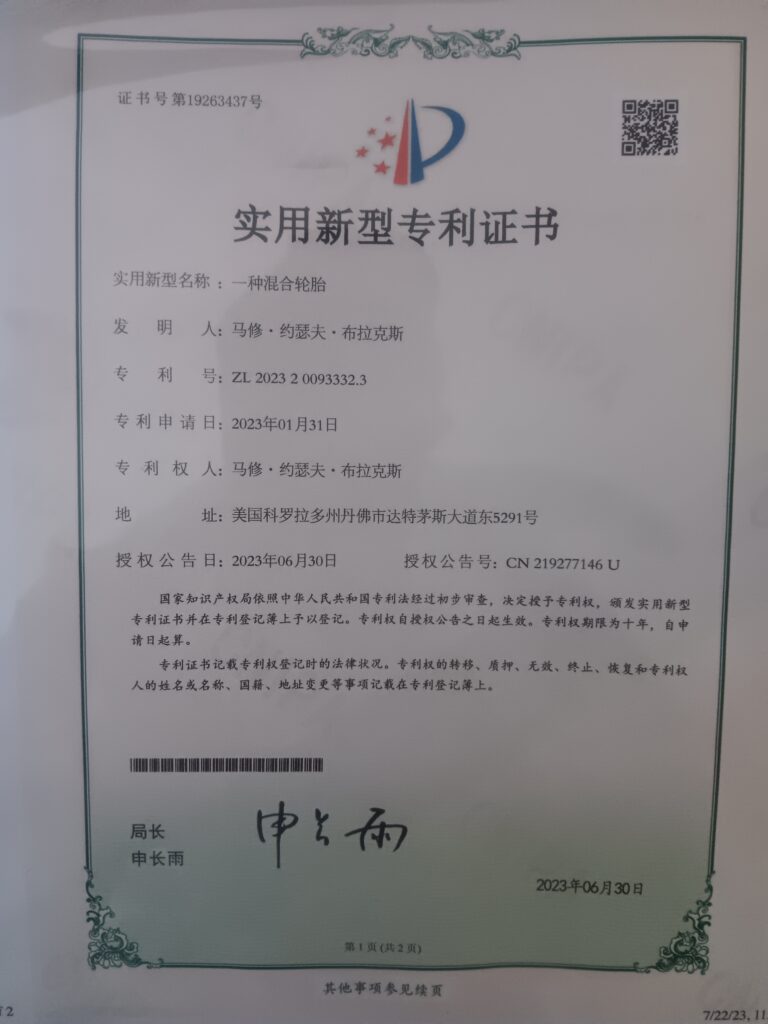

Awarded Patents & More

MolAct Tires operates as a licensing company with full ownership of our technology. Holding patents in both the United States and China, with additional patents pending in over 20 other countries, we boast a robust intellectual property portfolio. Backed by functional prototypes, validated materials, and cutting-edge techniques, MolAct Tires demonstrates a full system, ready for further growth.

Unlimited Potential

With their innovative designs, superior materials, and engineering expertise, MolAct Tires are at the forefront of both traditional and emerging vehicle categories, offering unmatched reliability across diverse terrains and environments.

Prototype- 2025

ReCo technology provides a foundation for a range of innovations, such as drive-up charging, real-time temperature activated SMA resistance adjustments, on-demand data, agricultural tires, and more.